DustRam® vs Dust Commander® Tile Removal Tool Comparison

DustRam® Dust Free Tile Removal

VIRTUALLY Dustless Tile Removal

Dust Commander® offers VIRTUALLY dustless tile removal while DustRam® offers DUSTFREE – a truly clean flooring removal, capturing dust at the source! DustRam® contractors receive the very best, tried, and job-tested, dust-free tile removal equipment available. They are covered through every step of their flooring removal projects. The accessories are durable and easily attached or detached based on the needs of the operator.

The chipping hammer, grinding shrouds and wheels, vacuums, and more are specially designed for easy use and speedy removal of all types of flooring or another surface. Finally, only DustRam® provides their licensed and certified contractors support through on-the-job training and technical advisement, marketing and SEO assistance, and ongoing contact and client referrals. Dust Commander® is unable to furnish any of this. Watch more videos of past projects.

JOIN OUR TEAM

Would you like to learn more about our dust free tile removal process? Contact our team today and ask us any questions you may have.

What You Should Know About Clean Tile Removal

1.Virtually Dustless is NOT, Dust Free!

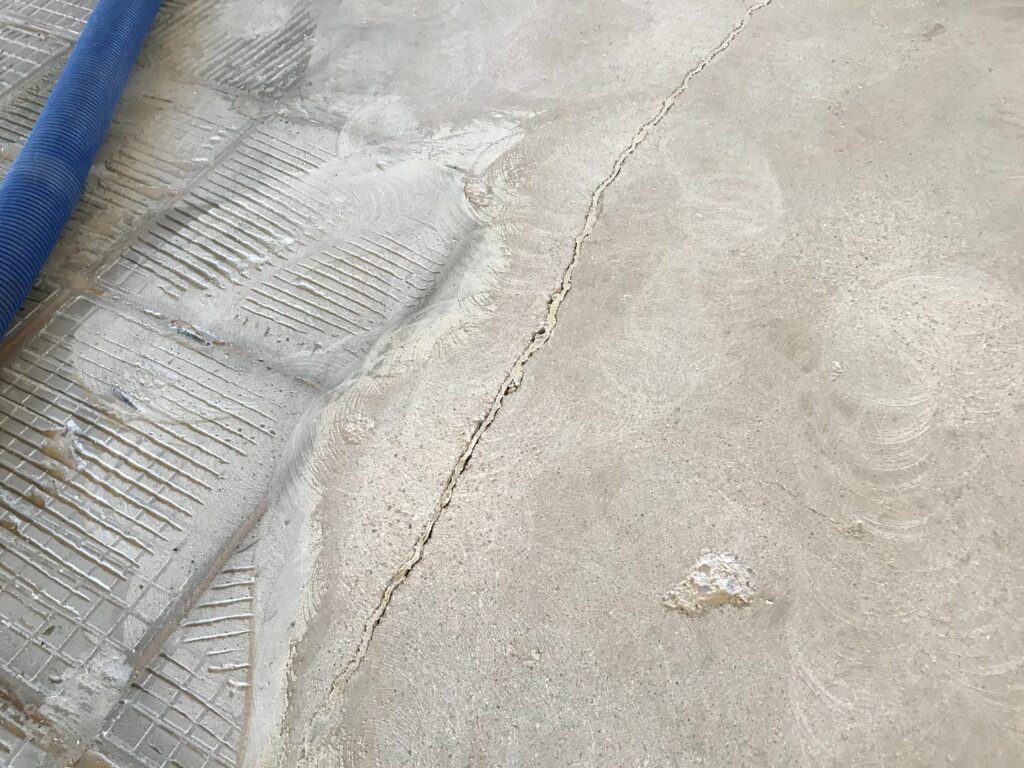

There is a vast difference between “clean” or “virtually” dustless and real dust-free tile removal. If one factor is in for a standard tile removal job where a pound of dust is created for each square foot removed, then an 800-square-foot job produces up to 800 pounds of silica dust. OSHA has categorized silica dust as a dangerous carcinogenic and ingesting or breathing it should be avoided at all costs.

A virtually dust-free removal usually advertises a 98% dust capture rate; out of 800 pounds that leaves 16 pounds of silica contaminants floating through the air conditioning vents and settling on food, clothing, electronics, and anything else within the home. Learn more about the dangers of silica dust.

2. A Truly Dust Free Process, Captures Dust at the Source!

To be dust free, these types of mechanisms must seize the dust at the source as it is being created. Once released into the home or business, only a long period of time and physical effort can remove the contaminants from the air and surfaces of a business or home. To combat the escape of concrete and thinset dust during flooring removal, an end-to-end system for dust free removal at every step of the process is necessary. Read about the evolution of DustRam®.

3. DustRam® Covers Each Aspect of Dust Free Flooring Removal

The DustRam® System is usually purchased as a whole package, including all the necessary components to collect the dust and eliminate the damage and mess created by traditional removal methods. The different DustRam® LLC devices cover each aspect of flooring removal and are well designed to maximize its speed and increase the efficiency of the operator. We are truly ahead of the competition.

4. Equipment and Tools Matter Greatly

The equipment is a crucial step, but as a DustRam® contractor, one has access to a complete operation from start to finish preventing contaminants from being released into the home or business. ***This is not fully possible concerning equipment currently supplied by Dust Commander®. Durability, the installation, removal, and maintenance of the attachment, and its job site usefulness are the base requirements for material on any construction project.

The components of the complete DustRam® system are rugged and made to last for years. Both the DustRam® and Dust Commander® chipping hammer attachments are made of durable aluminum and/or steel. Only the DustRam® has a hardened steel nose with a special design preventing debris from clogging where the tile chisel emerges from the attachment. Visit our FAQs page for more information. To learn more about our patented tools, visit our site.

DustRam® Products

Check out the DustRam® patented system of tools and equipment. If you would like to join our team of contractors or buy the equipment, contact us today.

Time Investment Difference Between Your System of Choice

There is a definite time investment difference between the DustRam® and the Dust Commander® when it comes to the maintenance and installation or removal of the chipping hammer attachment. A Metal DustRam® has one mounting bolt, which is secured and cannot be lost. The Dust Commander® has two but those are not secured and can be easily lost.

As seen in the previous video, the Dust Commander® chipping hammer attachment requires a total of 315 seconds to attach and detach, while the DustRam® quickly completes both tasks in 90 seconds total. The Dust Commander® bolts require additional tightening repeatedly during the use of the attachment. Time is money on the job site, and if one can provide less aggravation to the operator, they are more likely to take better care of the materials thus improving the life of the machinery.

System Usefulness and Productivity are Vital in Purchasing Equipment

Usefulness and productivity are vital considerations when purchasing machinery for use during construction or demolition. The DustRam® attachment allows the use of a Bosch® 11264EVS Chipping Hammer as a pry bar and helps to speed up the removal of well-bonded floorings such as tile, travertine, and Saltillo. This attachment is safe to use near baseboards, cabinets, and walls. The DustRam® chipping hammer attachment does not clog during the removal of thinset, tile, stone, or Saltillo. It channels concrete with minimal effort.

The Dust Commander® is unable to do any of these things. For fine-tuning during demolition, a contractor or flooring professional needs reliable grinding equipment including the best available shrouds and wheels. DustRam® skirts cannot be damaged while grinding thin-set or other drastically uneven surfaces and will still effectively trap the dust when used appropriately.

Have Any Questions? Contact Our Team.

Best Dust Free Floor Removal Vacuum On the Market

PulseRam® Self Automatic Cleaning Vacuum

PulseRam® by DustRam® captures tile dust at production.

The customized grinding wheels produced by DustRam® are of higher quality and designed to outperform all others on the market. The Dust Commander® cannot supply these to flooring professionals and contractors. The only way dust-free tile or flooring removal works is with the best vacuums in the business. PulseRam® vacuums are modified for performance, speed, and reliability.

PulseRam® vacuums can handle quantities of rough debris quickly and efficiently due to their design characteristics. These enhanced vacuum capabilities are not available through Dust Commander®. In general, DustRam® items are designed specifically to tackle an assortment of flooring demolition while remaining dust-free. The equipment and grinding wheels are used for removing all coatings such as sheet vinyl, wood glue, crack membrane, paint, epoxy, and more.

Nylon DustRam® Attachment Can Tear it Down!

Nylon®

The DustRam® (metal version) can even remove glued-down wood flooring. The Nylon DustRam® attachment effectively tears down fireplaces, hearths, showers, curbs, and tub surrounds as well as eliminating tiles from vertical surfaces such as stairs and risers.

Due to its patented design, the DustRam® chipping hammer attachment can remove the flooring and thinset up to the baseboards, inside corners, and fit under toe-kicks with ease. Finally, only DustRam® (metal version) trenches concrete for electrical and plumbing fixtures without damage to the attachment and is completely dust-free. Dust Commander® is unable to complete any of these tasks.

Contact Us Today

Would you like to learn more about our dust free tile removal process? Contact our team today and ask us any questions you may have.

After Purchasing Your Tile Removal Equipment

DustRam® Sets You Up For Success!

Once a contractor or flooring professional invests hard-earned money into equipment to make their projects run more efficiently, understanding the right way to use the apparatus is paramount. For a contractor to become certified by DustRam® requires 3 days of training in Tempe, Arizona.

Training will include setup, use, equipment maintenance, a 96+ page technical operator’s manual, and marketing advice specific to the contractor’s area. Dust Commander® provides only 1 hour of equipment setup…that is all. DustRam® provides support to the contractor after their purchase with direct access to Jack King, the inventor as needed for technical questions or advice via email or cellphone.

A DustRam® contractor receives customer leads from the company and is promoted on multiple websites, while their own DustRam® web page receives SEO optimization with marketing and administrative support. Additionally, the contractors and flooring professionals may use the manufacturer logo and website links for any advertising, including print, trailers, and online.

There is a continual increase in searches for dust-free and DustRam® over the past few years; the availability of cross-advertising gives the contractor a natural boost in exposure to the right client in their locality. Even after purchasing their implements, Dust Commander® does not provide technical assistance, training, or supplemental advertising.

DustRam® contractors receive the very best, tried and job-tested, dust-free tile removal equipment available. They are covered through every step of their flooring removal projects. The accessories are durable and easily attached or detached based on the needs of the operator.

The chipping hammer, grinding shrouds and wheels, vacuums, and more are specially designed for easy use and speedy removal of all types of flooring or another surface. Finally, only DustRam® provides their licensed and certified contractors support through on-the-job training and technical advisement, marketing and SEO assistance, and ongoing contact and client referrals. Dust Commander® is unable to furnish any of this.

Interested in Buying Our Equipment?

Would you like to learn more about our dust free tile removal equipment? Contact our team today and ask us any questions you may have.

TABLE OF COMPARISONS

Features and Benefits

DustRam® System

Dust Commander®

Has an end-to-end system of equipment for every process needed to provide dust-free tile removal?

| YES – Guarantee in writing to clients the finished project will be cleaner after completion than before the job started. |

NO – “Virtually??” Dust Free only

All system components are rugged

| YES |

NO

Equipment covers every aspect of the removal process and is well manufactured?

| YES |

NO

Design of the equipment maximizes the speed of the removal process?

| YES |

NO

YES – Aluminum

YES – Aluminum

Chipping hammer attachment NOSE made from hardened steel?

YES – Hardened Tool Steel

NO – Aluminum

Chipping hammer attachment NOSE designed to prevent debris from clogging the opening?

YES

NO

Mounting bolt(s) or clamps needed to connect the attachment to the chipping hammer?

1 Bolt

2 Bolt

Time needed to mount attachment to chipping hammer, includes greasing the chisel.

Approx. 75 seconds

(1 minute and 15 seconds)

Approx. 215 seconds (3 minutes and 35 seconds)

Total time needed to mount and dismount the attachment from the chipping hammer.

Approx. 90 seconds

(1 minute and 30 seconds)

Approx. 315 seconds

(5 minutes and 15 seconds)

Attachment mounting bolt(s) or clamps integral to the attachment?

YES

NO

Attachment mounting bolt(s) or clamps are retained securely during the mounting or dismounting process?

YES

NO

Attachment transforms chipping hammer into a powerful pry bar?

YES

NO

Speeds removal on well bonded tile, travertine or saltillo?

YES

NO

Equipment safe to use around baseboards?

YES

NO

YES

NO

YES

NO

Equipment DOES NOT clog while removing thin set, tile, stone, Saltillo or channeling concrete?

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO – 1 hour equipment set up only

YES

YES

YES

YES

YES

YES